Energy Management System

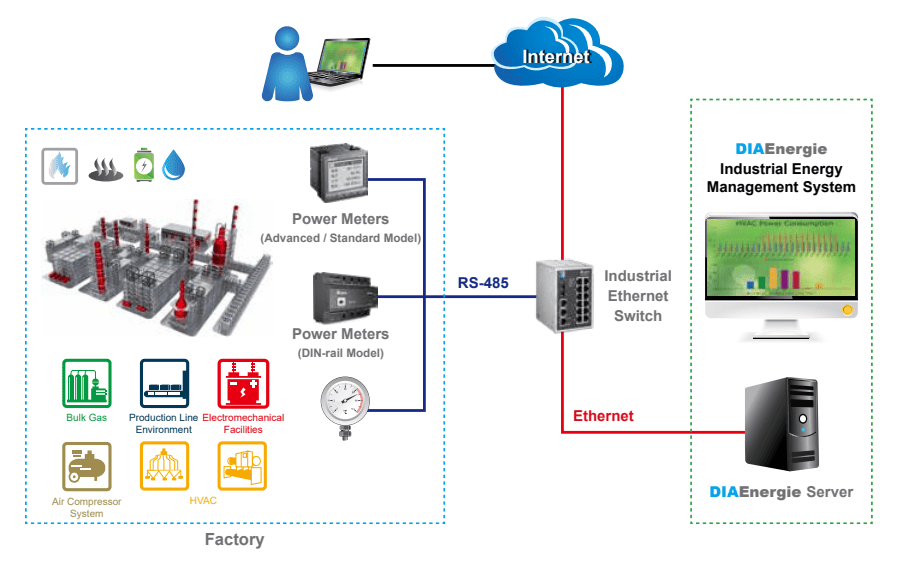

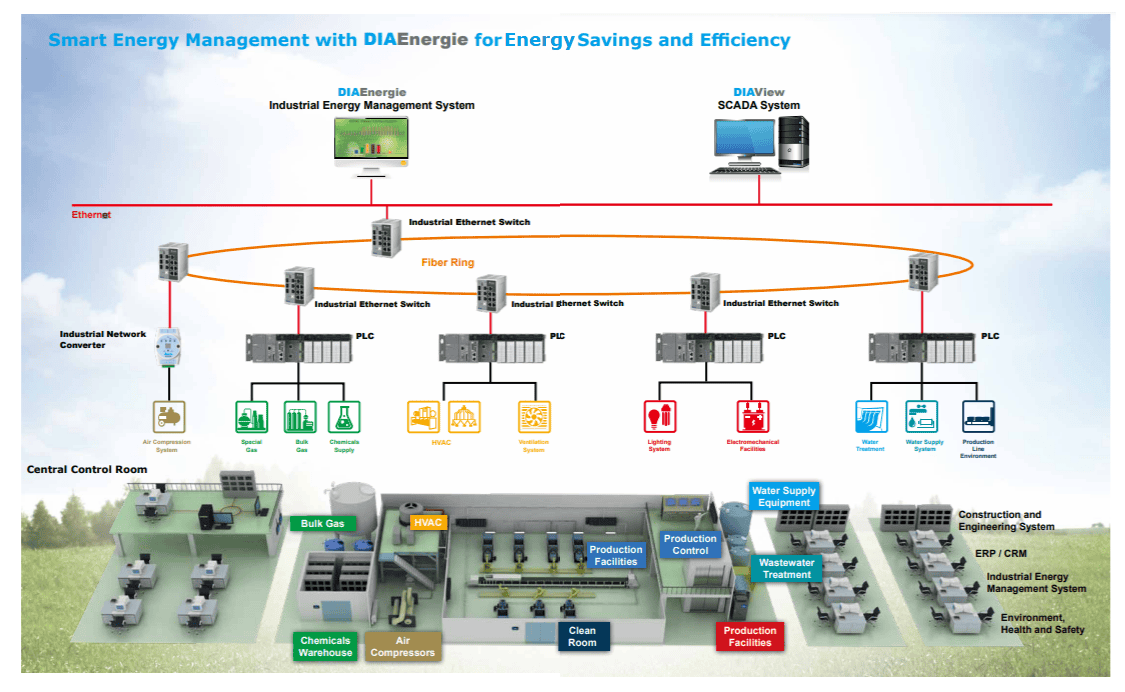

Through our DIAEnergie industrial energy management system, we collect data from all aspects of the power system, especially high-energy-consuming equipment, conduct systematic analysis of the data, and discover abnormal energy consumption and energy-saving areas. By continuously optimizing equipment operation efficiency, improving production processes and formulating energy management strategies using Delta’s solution, we help you to achieve energy usage efficiency. Our DIAEnergie EMS software uses a systematic approach to provide a basis for companies to analyze their energy consumption structure.

Challenges in Energy Management:

-

TNB Maximum Demand Penalties

Commercial and Industrial Companies often face penalties for exceeding their contracted maximum demand. Without proper monitoring and planning, factories may unintentionally surpass these limits, resulting in significant additional costs. -

Resource Inefficiencies

Many factories may experience energy wastage due to inefficient processes, outdated equipment, or poor operational practices, leading to higher energy consumption and costs. -

High Operational Costs

Companies with high energy consumption face substantial operational costs due to high electricity tariffs and poor energy management.

We help you transform your Energy Challenges into Sustainable Solutions with Delta’s Energy Management System

Reduces energy cost.

Power usage monitoring and visualization, and abnormality detection to find more possibilities for energy savings.

Monitors equipment power efficiency and expands their service time.

Discovers reactive and excessive power consumption to avoid electricity fines.

Provides reports on energy saving and efficiency comparison for reference.

Functions

Long-term Tracking

Comparison by period and usage trend tracing.

Data Analysis

Detailed energy data analysis, regression predictive analysis, electricity cost analysis.

Alarm Management

Real-time alarm notification for operation & maintenance team.

Real-time Monitoring

Real-time data in consumption and power usage by various perspectives (equipment / area / region), carbon emission tracking.

Integrated Information

User-defined dashboard for UI needs, correlation analysis between energy usage & specific factors & gap identification for energy-saving.

System Structure and Applications